Pkw K1 Kübelwagen Typ82 1:16 Modelik

Page 3

Wiper motor,window hinges and stoppers for the windshield

| The part to be used for the motor. |

Part assembled and the printed switch is to be replaced with the "knob" |

Motor mounted |

Window in upward position |

| Window in downward position. |

The hinge |

And the stopper knob |

The front fenders

| Here are the parts to be used.The parts are laminated so it also will have color on the backside. |

Edges are painted to avoid the white stripe along the joint |

Here I have started to glue the biggest arch to the fender.It's a bit tricky to get it to be nice since there aren't any jointstrips or flips to glue the archer to. |

The part is sucessfully glued in place |

| Next out will be this narrow arch....about 1mm thick. |

Fenders done |

Overview |

Closeup |

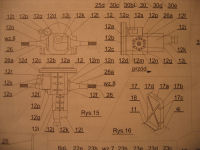

The front seats

| The drawing of the seats. |

Here I have cutted out all the parts for one seat. |

First thing was to laminate the seatparts and the back parts.I have also marked on the seat where the buttmark will come. |

I used my Dremel to carve out the "buttmarks" in the seats |

| The covers are applied, and the cushions are ready to be assembled into a seat. |

The cushions are put into the frame |

And we have a seat |

The seats are connected to their "feets" |

| Overview. |

And placed into the car just to see how they fit. |

They fitted just fine |

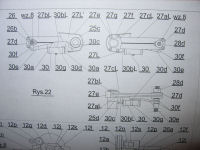

The rear axel,suspension and transmission.

| Drawing of the arms that is going to hold the axel and transmission. |

A lot of parts to be used for this job. |

Here I have mounted the first one.Half painted |

Half of the second one with the 1mm nuts in place |

| Closeup. |

Closeup. |

Construction of the second arm.The parts to use are cutted out and are ready for assembly. |

First out is making the small sylinder.The part is rolled against a 2mm rod to get the right size of the finished part. |

| The sylinder is done, and the tiny roll to be mounted on the bottom is rolled against a 0,6mm rod.The end plates are also ready to me glued in place. |

Sylinder are glued to the plate, and the 3 distance keepers are done.Rolled agains a 1mm rod to be placed on spots c and d. |

The sylinder mounted on the arm. |

And the arm is placed where it should be |

| Painted. |

Chalkdusted. |

This part is the first of at least 3 construction points.. |

The drawing of cp2shows that this is a very simple job. |

Construction point2 of the rear axel,suspension and transmission.

| It's just 5 parts involved,exept the small strips, and all the main parts are glued to 1mm karton.Strips are glued to 0,2mm karton.. |

The parts are mounted, and the axel is inserted to see if I got it aligned. |

Overview |

Overview |

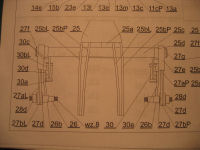

Constructionpoint nr3 is the rear transmission.

| The drawing. |

All the parts are cutted out. |

The rear part is laminated of 5 parts. |

The two "boxes" is underway |

| The main parts done |

The part is finished. |

All parts are mounted loosely on thers positions just to see how it all fits. |

Another view of the part |

| And put on the car to see how it fits there.It fitted just fine, but I have to wait with the gluing until the engine is in place....and that will be another story |

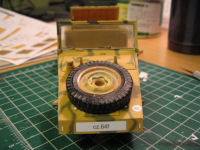

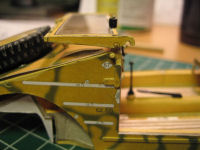

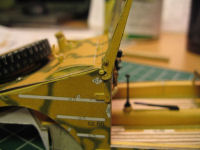

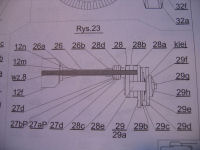

Constructionpoint nr4, the wheel connectors.The drawing shows that this is a straight forward assembly. |

Parts cutted out...still amazed by the number of parts for this build.... |

The main parts put together. |

| Front view. |

Rear view. |

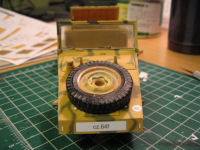

And I put the wheel on just for fun....So now I'm going to put some paint on the parts and glue it all together. |

As I didn't have enough small details to work with.....I decided to put nuts and bolts on the wheel since my plans for a diorama involves the change of a broken tire.....and I wanted the bolts to show when the wheel is removed, and the nuts lying on the ground on a dirty/oiled piece of clothing. |

| All five bolts in place. |

All five bolts in place. |

The nuts. |

Nuts and bolts in place |

| The plate with the bolts are glued in place into the wheel connector. |

And an overview.There are still some details I want to have in place before eveything is painted and glued in place. |

The workshop with the parts |

The rear parts |

Gallery of the finished model is HERE

©Johnny Svensson 2007

|